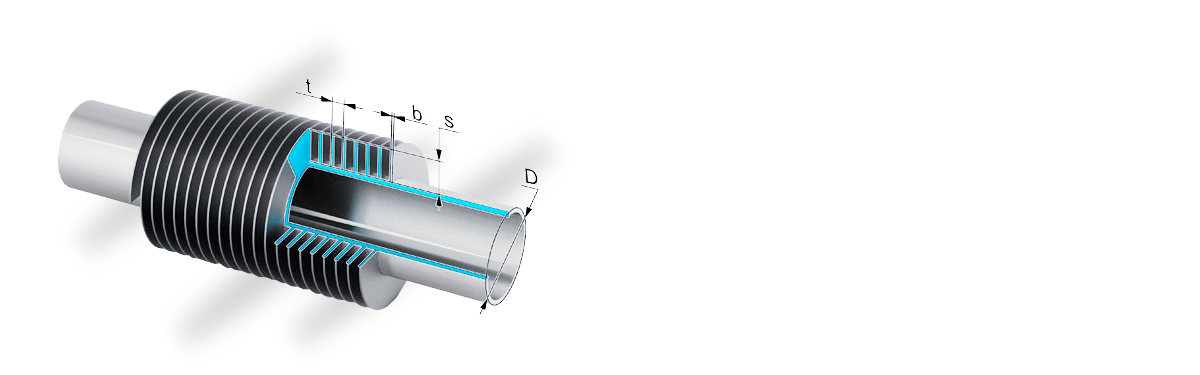

ТВЧ finned tube is a 2-element structure:

- Bearing inner tube of brass, stainless steel or nickel silver. Brass is used in H and M tubes (fresh and low mineralized water), stainless steel (as a rule 12Х18Н10Т grade) and nickel silver (copper-nickel alloy) in M2 and M5 tubes for highly mineralized and salt water.

- Ribbing ensuring high conductivity. As a rule ribbing is made of aluminum, sometimes copper. Larger area of ribs provides for several times higher conductivity.

ТВЧ finned tubes are called after the process of their production: high-frequency welding. During the production process a bearing tube and winded metal strap are heated to high temperatures by high-frequency current (ТВЧ). As a result of root high-frequency welding a stiff joint resistant to outdoor unfavorable effects appears. FORK,OOO manufacturing facilities are able to produce ТВЧ finned tube of the following parameters:

- Tube length (in мм): 1000 – 15000;

- Ribbing height (in мм): 8 – 28;

- Coil pitch (in мм): 3,8 – 25.

Tube parameters:

- diameter (в мм): 20 – 219;

- wall thickness (мм): 2 – 12;

- Material: steel, as a rule 12Х18Н10Т grade, brass, nickel silver.

Ribbing considerably enhances conductivity and makes wide use of ТВЧ tubes in power engineering, metallurgy, chemical and petrochemical industry and boilers possible. Finned ТВЧ tube operation range depends on its design. For instance, УХЛ models are suitable for regions with moderate and cold climate; М5 allows using salt water as coolant, etc. Sometimes when a ТВЧ finned tube is ready an additional protection layer is applied by the hot galvanizing method. The choice of an appropriate ТВЧ finned tube brand depends on operation conditions, climatic region, characteristics of water used as a coolant. If you have any doubts and can’t make the right decision, ask our specialists. They will help you to make a choice and order.

- Оребренные трубы