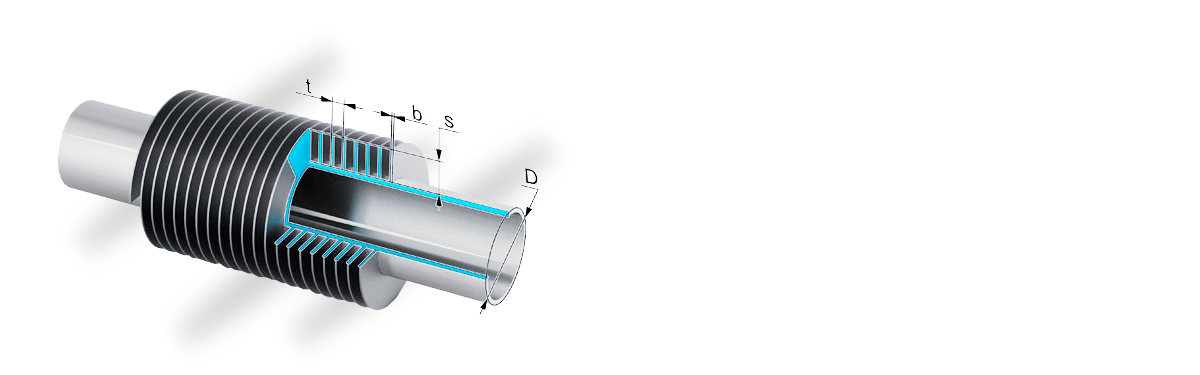

Oil cooling which is possible due to oil coolers is necessary for faultless operation of the industrial equipment. This equipment removes heat, which is formed during the working process of friction parts (bearings etc.). Oil coolers have standard design: casing, tube bundle, two caps: inside and outside. Oil circulates the whole system around a closed path thanks to baffles, which are located lengthwise the reinforced pipes, which form a tube bundle. Plastic sealants provide connections leak tightness and prevent from oil leak along technological gaps. Oil cooler outside cap has two pipe nozzle for water supply and water removing, the temperature gages are mounted on each of the pipe nozzles. Shank bore is devided by the baffle and thanks to it the oil cooling is getting more effective. Inside cap is mounted in the lower tubeplate with a small gap taking into account tube bundle’s thermal extension. Oil cooler casing’s flange has an air opening. Our company offers the following series of oil coolers: МБ, МО, Ц, ДЦ, ОДЦ, each of these models has its own field of application.

- Oil coolers series МБ are for oil cooling in steam and gas turbines and designed for the systems of control and lubricating.

- Oil coolers series МО are for providing a stable operation of hydraulic equipment (machines, press groups), for oil cooling in large electric motors, hydrogenerators.

- Series Ц is mounted for insulating oil cooling in furnace and power transformers, general-purpose transformers in case cooling system Ц is applied.

- Oil coolers ДЦ are for cooling of oil-transformers, autoconnected transformer, general-purpose electrical reactors where cooling system ДЦ is used.

- Oil coolers series ОДЦ are installed in side-mounted, outdoor and attached systems, transformer blocks. These heat-exchange units are for devices with ДЦ system.

All oil coolers produced by our company, are technically inspected and comply with GOST requirements.

- ОДЦ-180

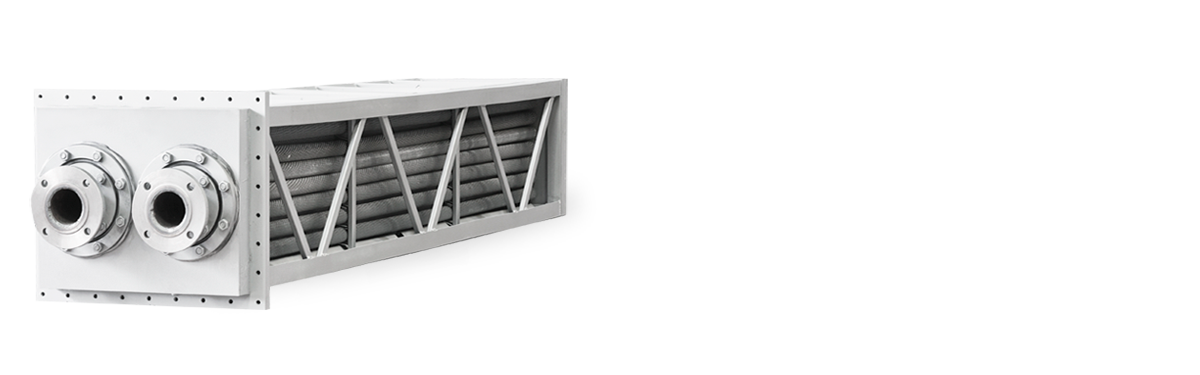

- Маслоохладитель ДЦ

- Маслоохладитель Ц

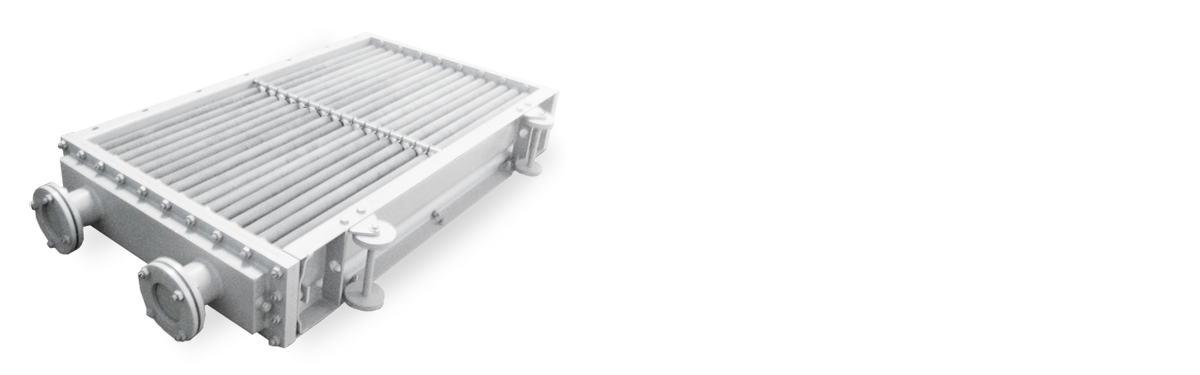

- Маслоохладитель МБ