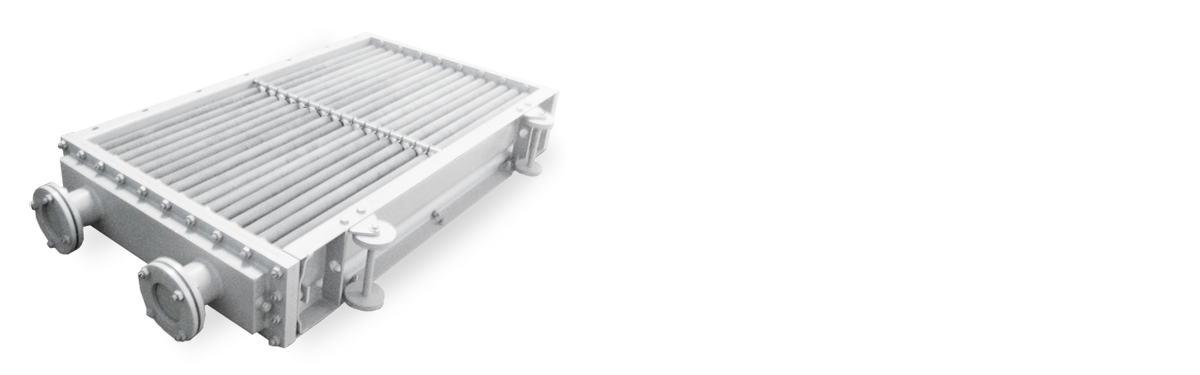

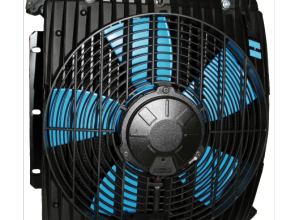

ДЦ air cooler is a type of equipment cooling stationary power and autotransformers. It is installed in cooling systems. It generates artificial air and oil circulation with installed pumps. ДЦ consists of:

- ДЦ oil cooler;

- Vacuum tank;

- Vacuum pump;

- Electric pump;

- Cooled transformer;

- Lamellar filter;

- Absorbing filter.

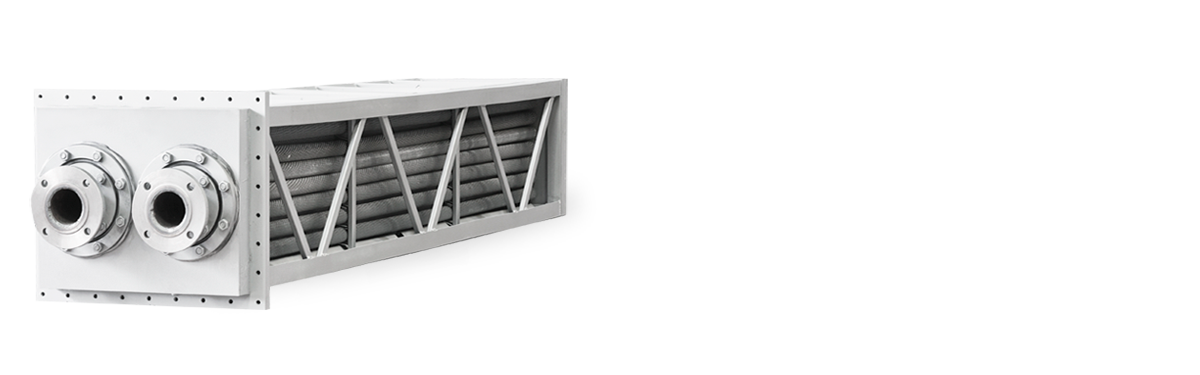

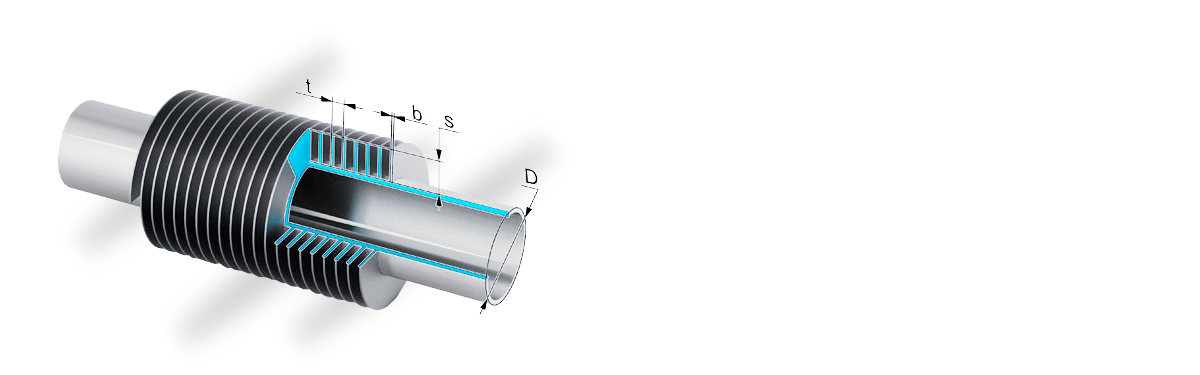

The design of a cooler is based on a system of finned bimetal tubes (tube bundle) placed in a body. The number of oil cooler tubes defines its power. Oil goes through 2 or 3 cycles inside depending on cooling system design. How does ДЦ series cooler work? An oil cooler is connected to the oil pipeline by 2 flanges – inlet and outlet. Coming through the inlet flange oil passes through the system of finned tubes dissipating the heat in the air, pumped inside, and goes out through the outlet flange. Filters installed at the outlet clean oil from debris. Installed pressure sensors (manometers) monitor pressure and ensure stable work of the whole system. ДЦ cooling system provides for installation of minimum 2 more oil coolers and one standby cooler in case of emergency. The coolers are automatically switched on but can be also (if necessary) activated manually. ДЦ series oil cooler model is marked: ДЦ-180/2280-У1

- ДЦ – series;

- 180 – – heat flow (cooling power) in KW;

- 2280 – is a distance between end tube walls in millimeters;

- У – climatic design (У – moderate climate, ХЛ – cold, Т – tropical).

- 1 – operating conditions, in this case – in the open air.

Oil temperature in the upper layer of a tank is the main indicator of oil cooler efficient work. Its maximum value must not exceed the limit of +75+800С. You need to control ribbed surfaces visually. Do not allow ribbed surfaces to be dirtying as it reduces transformer oil heat exchange. Mechanic cleaning is necessary if ribs are dirtied. There’s a need for permanent control of the present connections for oil leaking to be found and disposed of.

- Маслоохладитель ДЦ