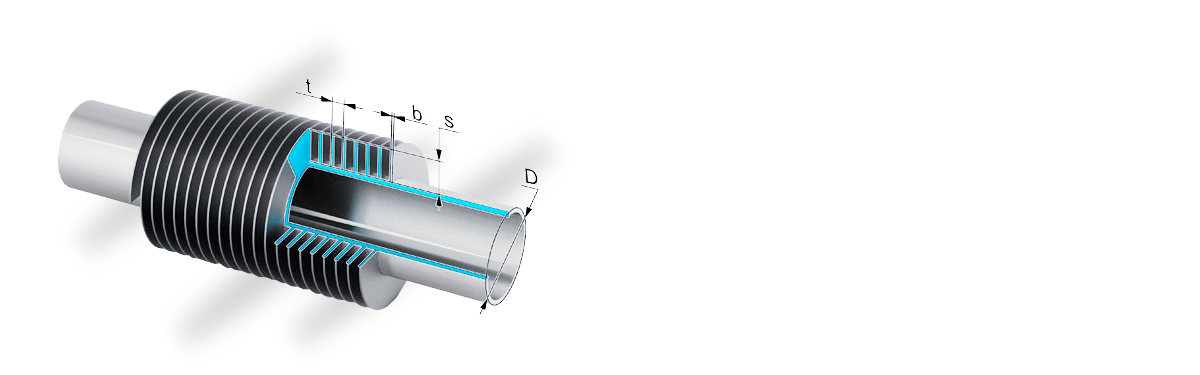

A finned tube is a basis for the most of industrial coolers. It consists of an inner (bearing) tube transferring cooling or cooled substance, and outer ribbing enhancing the area of a heat exchange surface. Each element meets its requirements: bearing tube to be durable and resistant to corrosion, outer ribbing to have sufficient thermal conductivity and provide rapid heat exchange. Initial material for bimetal finned tube is a smooth tube made of brass, stainless or carbonaceous steel, nickel silver or other alloys depending on the type of water it is intended for. Bimetal finned tube of Н and М grades (low degree of water mineralization) has a brass bearing tube. 12Х18Н10Т grade of stainless titan steel and МНЖМц 30-1-1 grade of nickel silver (copper-nickel alloy) are used with salt and mineralized water. Both materials are resistant to corrosion and used for operating under unfavorable conditions. Ribbing of a bimetal tube is carried out with aluminum by knurling (extrusion). Another name for such tubes is extruded (E-Fin). The process of ribbing by extrusion takes 2 steps.

- 1st step: aluminum strap/tube is forced on a bearing tube of brass, steel or nickel silver. Stiff bimetalic structure is set up.

- 2nd step: helical knurling of ribs onto aluminum layer is done at +3500С to avoid melting.

This way, the outer surface is fully covered with aluminum and provide for high corrosion resistance combined with mechanical durability of a stainless steel, brass or nickel silver bearing tube. Knurling ensures high density of two materials bonding important for efficient conductivity, and stiff knurled ribs are resistant to thermal deformation. Ready bimetal finned tube can be used for production of heat exchangers with operating temperature up to +3000С Any alloy sustaining ribbing loads can be used as a material for an inner (bearing) tube production but ribs are always aluminum.