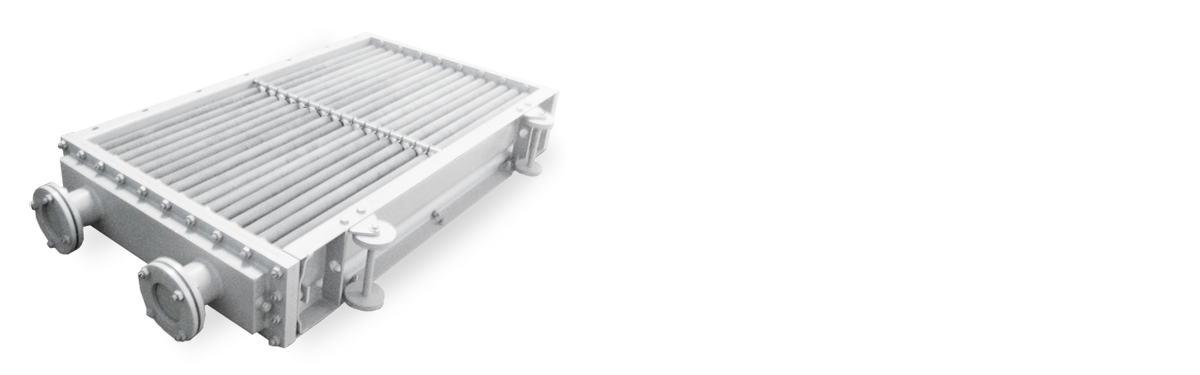

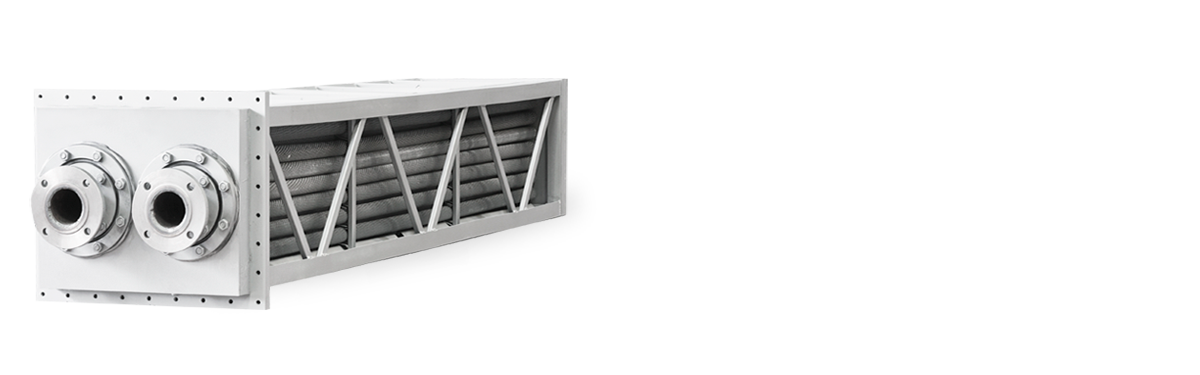

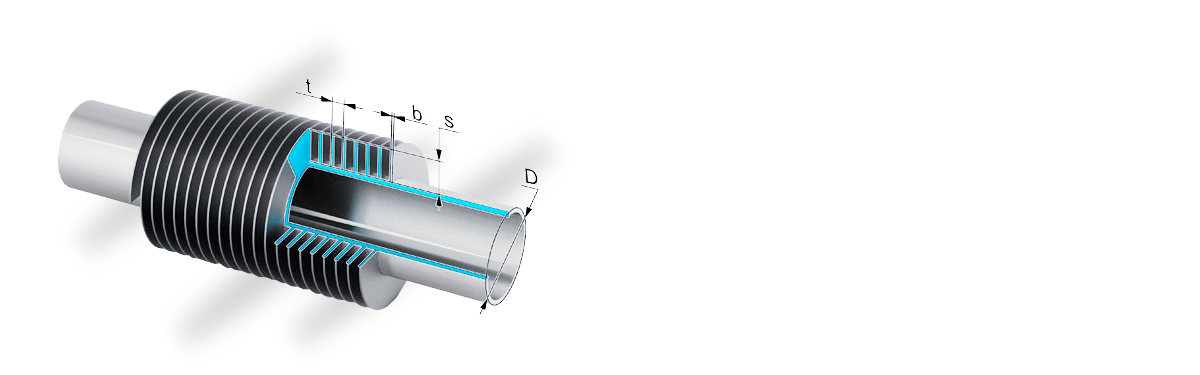

МО water coolers are intended for industrial electric equipment and installed inside. They cool oil cycling inside closed loop system of generators, electric engines, hydraulic equipment (presses, lathes, compressors, etc.), refrigerating plants. It is mainly used for cooling aviation, turbine, diesel oils and other non-aggressive liquids having zero corroding effect on aluminum alloys at temperature no more than +700С, and outer air temperature range +1 – +550С. Process water of industrial water supply system with a temperature range of +5+300С serves as a coolant. МО water oil cooler is a system of bimetal finned tubes (tube bundle) in a steel body. Cooler water tanks are equipped with water inlet and outlet nozzles. There’re also transporting and mounting hinges. Body and water tank materials are stainless steel and alloys, corrosion resistant – brass, nickel silver, etc. Tubes are of stainless steel, brass, titanium alloys, ribbing is of aluminum The choice of oil cooler material depends on type of water it works on: fresh (design Н), mineralized (М. М2) or salt (М5). М5 oil coolers are produced of alloys with the highest resistance to corrosion and aggressive environment. МО oil cooler principle of operation consists in heat transferred from a warmer substance to a cooler one. In our case it is from oil to water. Water coming through the inlet nozzle passes several cycles cooling oil and leaves through the outlet nozzle. The system of ribs enlarges the heat exchange area significantly and makes oil cooler operation work efficient. МО oil cooler is marked: МО-10-М-УХЛ4.

- МО – oil cooler series;

- 10 – heat flow (cooling power) in KW, in the present case not less than 93 KW;

- М – mineralized water (Н – fresh , М5 – salt).

- УХЛ – for operation in moderate and cold climate (Т – tropical);

- 4 – operation conditions. Here – operation indoor with artificial conditioning.